3D Prototyping

In 2012, with the rise in popularity of 3D printed plastic parts we decided to invest in a 3D printer. As a large amount of our work requires custom brackets, enclosures and parts. Therefor a piece of equipment that can make complex plastic parts without a tooling charge was a fantastic investment. In early 2015 we upgraded to an Ultimaker 2, which in late 2016 we then upgraded to an Ultimaker2 + to allow use to print better quality parts with a higher level of accuracy. In 2019, we added a Raise3D Pro2 professional 3d printer to our equipment giving us the capability to 3d print a solid cube with 30cm sides if required. During the Covid-19 outbreak, Winter and Smith produced 120 3d printed PPE facemasks for the charity appeal launched by 3d-crowd.uk So far we have used them to create:

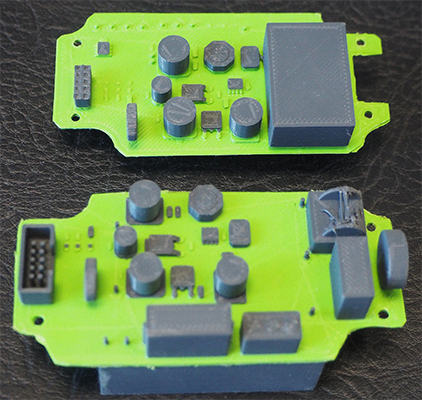

- Camera housings for CCTV modules

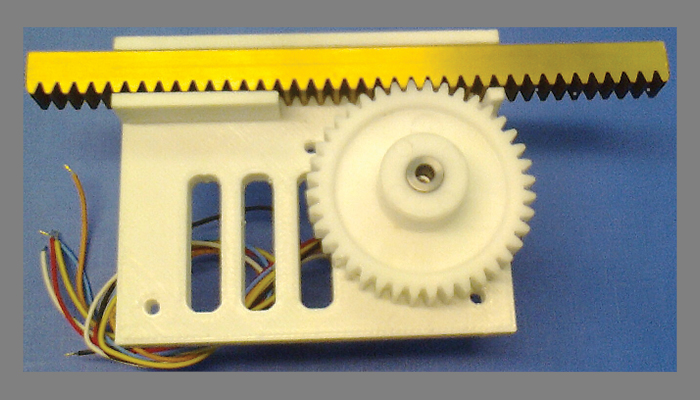

- Gears and cogs

- Mounting brackets for slides/gearboxes

- Small enclosures

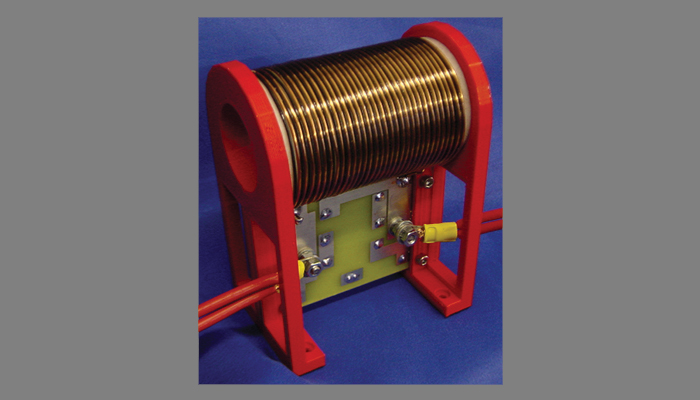

- Inductor support brackets

- Motor Support Brackets

- PPE Facemasks during the Covid-19 outbreak

- Stands for the display of customer equipment