Reverse Engineering

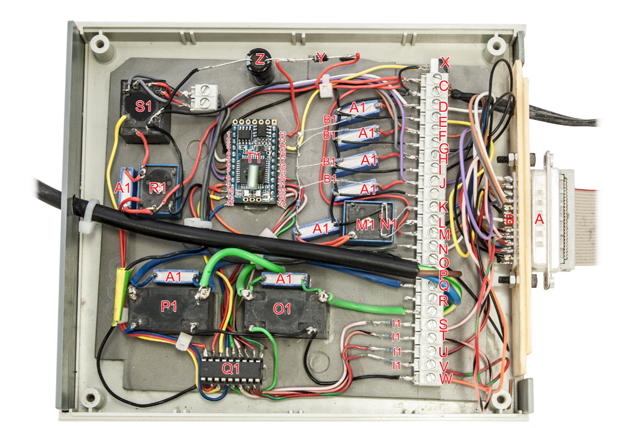

Many of our customers have had products made in the past that they are no longer able to obtain or have designed an electronics circuit that does the job – but is very hard to duplicate in production volumes. Sometimes they have been designed on Veroboard or Breadboard, or even various components wired together that do the Job. The unit pictured below was recently re-engineered by Winter and Smith. This unit had been used by a customer for over 10 years, before they required 11 more of them. It was either a case of spend many days building a duplicate of the current product (no drawings or schematics existed) – or ask for professional help.

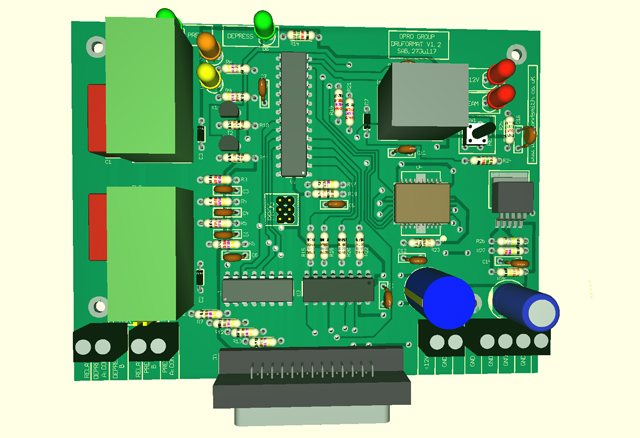

Winter & Smith disassembled the unit component by component, and piece by piece built up a circuit diagram of the design. We then looked at the design and made several recommendations of changes to various parts of the circuit, to optimise it and make it more reliable. In this instance we replaced a part costing over £60 with one costing £1.50. The customer accepted all the changes, and we then designed the new controller pictured below and manufactured 12 of them.

Quite often, a customer comes to us with a circuit board or a product that they used to make or buy but are no longer able to. This can be due to several reasons such as:

- The original designer/manufacturer no longer exists

- The designs were done in an old CAD system, or were done before CAD existed (We have even re-created a product from hand drawn schematics from 1978)

- The boards exist, but the parts are obsolete or no longer available (we can find alternative ways of doing it)

- Staff have left, taking with them the knowledge (we can look at the design, and create a new version of the project – ensuring that the data is in a format that the client can keep and use in the future)

- Drawings and data have been lost / misplaced (we can reverse engineer from an old circuit board)

Winter and Smith are more than happy to reverse engineer circuit boards and systems for clients, if they can prove they have ownership of the design, or the legal right to do so. In the past we have reverse engineered products for products such as:

- Machine controllers for the Pyramid Tea Bag factory

- Circuit breaker monitoring equipment

- Motor speed monitoring equipment

- Alarm Panels

- Electronics equipment for the oil/gas industry

Our normal method of working is to reverse engineer the product in its existing format to produce schematics, PCB layouts and Bills of Materials. At this point we will inform the client of any obsolete parts and then if necessary modify the design to use modern parts. If a unit contains software that the customer is not able to provide, or copy from an existing EEPROM/storage device – we are capable of fitting an alternative processor and writing new software to a specification.