Electronic Manufacturing

Winter and Smith have been manufacturing electronics equipment for over 50 years and specialise in low to medium volume manufacture for a large variety of customers (Including a number of high profile clients). Our manufacturing services can be tailored to uniquely suit your requirements:

- Full box build solutions - We do everything, and supply a product ready for shipment to the end customer

- Assembly only - Clients supply the parts, and we assemble the product using them

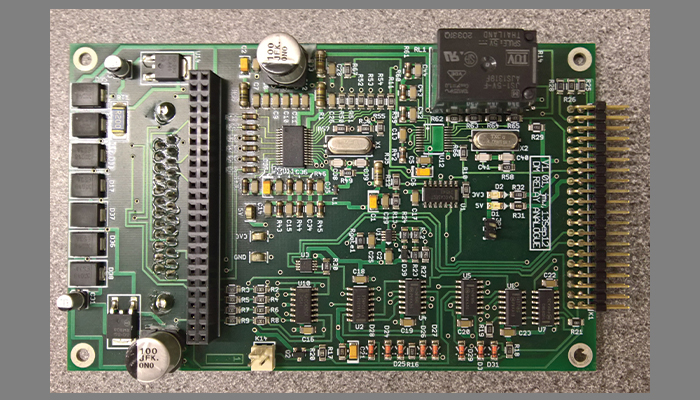

- Circuit board assembly - We build and test boards, and ship them to our clients to fit inside equipment they are building

We have fully RoHS compliant manufacturing facilities, and are capable of both Surface Mount (SMT), Through Hole assembly and complete product builds. Our facilities include :

- Neoden K1830 fully automatic pick and place machine

- TWS Quadra DVC, camera controlled fully automatic pick and place machine

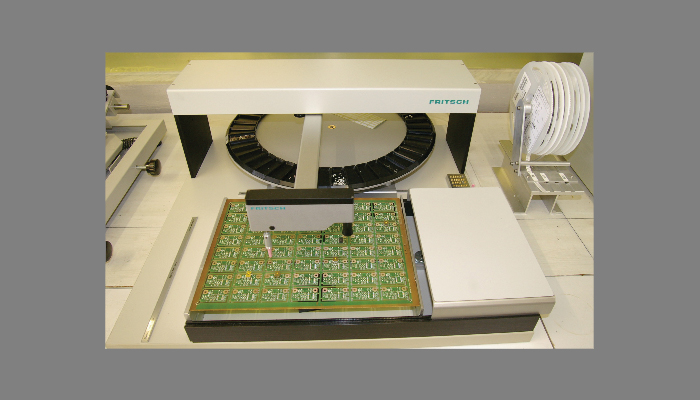

- Fritsch manual SMT assembly machine

- Two TWS Reflow ovens

- Fritsch solder paste application table

- 4 off TCS/4 manual through hole assembly jigs

- Ersa HR1000A SMD rework station

- High magnification board inspection camera system

- Full electronics test facilities

- Full prototype test jig manufacturing facilities. (Including the development of Rigs that interface with PC software)

Many customers also take advantage of our custom test jig design service, where we can design a bespoke piece of equipment that tests all of the features of their hardware. Some of these are also linked to custom PC software, to automate and log the testing process (One system even incorporates a label printer, to print the test results for each product tested). We have also taken numerous customers equipment for EMC testing, and are able to offer advice on any issues found.